Blog

Reasons for front wheel bearings to breakdown

Car wheel bearings are an important component of a vehicle. They are designed to support the weight of the vehicle, and provide a smooth rotation of the wheel on the road. However, over time, car wheel bearings do deteriorate for various reasons.

Wheel bearings, like any other mechanical component, are subject to wear and tear over time. They can eventually wear out due to the normal wear and tear associated usage.

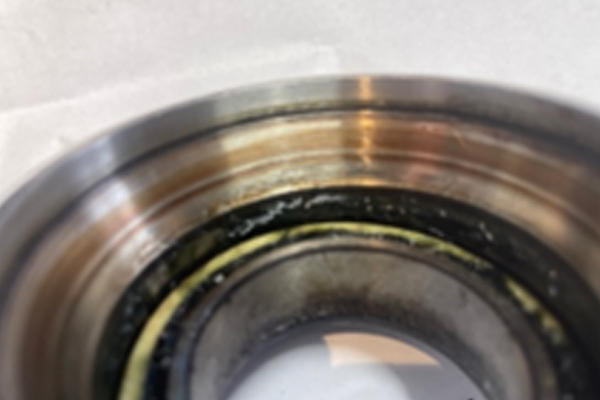

Before sealed bearings were used one of the reasons why car wheel bearings deteriorated was due to contamination. Dirt, debris, and other contaminants entered the bearings, and will caused damage over time. This caused the bearings to wear out faster and fail prematurely.

Car wheel bearings are designed to support a certain amount of weight, and if they are overloaded, this will cause undue stress on the bearings lead to deterioration. Overloading will cause the bearings to wear out faster and even crack or break. Do not overload your roof racks or boot.

Car wheel bearings can also deteriorate due to impact damage. This can occur if the vehicle hits a pothole, curb, or other obstacle. The impact can cause damage, cracks, or other types of defect that can impact the bearings.

When going over a bump in the road, or a pothole the font wheel bearing bears the full weight of the car plus the velocity of the vehicle in a downward / forward pressure. Generally having landed in the pothole the driver will swing the car left or right to avoid the rear wheel landing in the same pothole. This hard sudden swing puts huge extra pressure onto the front bearing.

There are several factors that contribute to the different degree of wear between the front and rear wheel bearings

- Approximately 75% of the breaking force is applied to the front wheels and only 25% to the rear so that even under normal driving and braking conditions there is more strain on the front bearings. Harsh or emergency braking brings even greater pressure to bear on the bearings.

- Turning at high speed exerts extra load on the front wheel bearings.

- Turning even at 40 to 50 klms/hr adds pressure on the front bearings..

- Road conditions also play a role; front wheels bear more stress due to sharp turns, obstacles, potholes and sudden stops.

Identifying potential issues that may cause deterioration.

While the rear wheel bearing rotate in a fixed vertical plane the front bearings both rotate in a vertical plane and also rotate about its axis when turning left or right. When turning increased centrifugal sideways pressure is exerted on the wheel bearing.

A broken front wheel car bearing can significantly affect the steering and braking of the vehicle, leading to potentially dangerous driving conditions. Here are some ways a broken front wheel bearing can affect steering and braking:

When a car goes over a pothole, the wheel bearings are subject to several forces that can cause damage or wear on the bearings. These forces include:

When a car’s wheel goes into a pothole, the wheel and tire are forced downwards, causing an increase in vertical forces. This compresses the suspension system and places additional pressure on the wheel bearings. As the wheel goes through a pothole, it experiences torsion forces, which occur when the wheel twists around its central axis. These forces cause the bearings to move in unexpected ways and lead to increased friction, wear and ultimately, failure.

If the pothole is not straight but at an angle, the wheel’s motion is not just up and down. The wheel will experience lateral forces, which can cause the bearings to twist and put additional stress on them.

Collectively, these forces create additional loads on the wheel bearings that are not normally present during typical driving conditions. Over time, repeated exposure to potholes, uneven surfaces, and road debris can cause the bearings to wear and tear, leading to damage, deterioration or even complete failure of the bearings. That’s why it’s important to maintain and inspect the bearings regularly to ensure that they are in good working condition

……………………

When a front wheel bearing is broken, it can cause the brake pads to wear unevenly or become misaligned. The broken bearing can cause the wheel to wobble or tilt, causing the brake pads to apply uneven pressure to the rotor. This can result in a pulsating or grabbing effect during braking, making it difficult to stop the vehicle quickly or predictably. ABS system: Many modern vehicles are equipped with antilock brake systems (ABS), which rely on wheel speed sensors to detect when the wheels are about to lock up. When a front wheel bearing fails, it can cause the wheel speed sensor to malfunction, resulting in inaccurate readings that can affect the performance of the ABS system.

If the wheel alignment and camber setting are incorrect there will be significant affects on the life of the wheel bearings. When a car’s wheel alignment is incorrect the wheels to not rotate in their proper position, causing more stress on the wheel bearings. A misaligned wheel can cause the wheel to tilt or lean to one side, which can put an uneven load on the bearings. This will lead to increased wear and tear on the bearings and shorten their lifespan. Poor wheel alignment will cause the tyres to wear unevenly, which causes vibrations, and impact the bearing life.

Camber refers to the angle of the wheel concerning the road surface when viewed from the front or rear of the car. If a car’s wheels have too much positive or negative camber, it can cause the wheel bearings to wear unevenly. A positive camber occurs when the top of the wheel is leaning outwards, while negative camber occurs when the top of the wheel is leaning inward. Both types of camber will cause stress to the bearing, cause uneven wear, and shorten the bearings’ lifespan.

Incorrect camber also puts unnecessary strain on the suspension components of the car, including the wheel bearings. A car with misaligned wheels and an incorrect camber is more likely to experience uneven wear and tear on suspension components, leading to the bearings losing their strength quickly.

Symptoms to watch out for

1. One of the earliest signs of a worn-out front wheel bearing is a grinding noise that typically increases with the speed of the vehicle. The noise is heard when the wheels are in motion, and it gets louder when turning a corner. The sound will be louder if the wheel bearing is particularly worn and may also be heard when braking.

2. Another symptom of a worn-out front wheel bearing vibrations are felt in the steering wheel. The vibrations may be more noticeable at higher speeds and will increase with the level of wear and tear on the bearing.

3. Front wheel bearings that are worn can cause the tyres to wear unevenly, particularly on the outer edges of the tyre. If you notice that your tyres are wearing out more quickly than usual, it could be a sign that the front wheel bearings need to be replaced.

4. When a front wheel bearing is worn, the steering may start to pull to one side, particularly when turning a corner or going around a bend. This is because the worn bearing is causing uneven movement of the wheel and affecting the alignment of the steering. . A broken front wheel bearing can cause the steering to feel loose and imprecise. When a wheel bearing becomes worn, it is no longer able to hold the wheel securely in place, resulting in the wheel moving back and forth slightly. This movement will cause the steering to feel loose and unpredictable, making it difficult to keep the vehicle in a straight line

5. Faulty shock absorbers can adversely affect the wheel bearings of a vehicle in a couple of ways. Increased stress and load: Shock absorbers are responsible for controlling the vehicle’s suspension and resisting the shock and vibrations from the road surface. If the shock absorbers are faulty or not working correctly, they may not be able to control the up and down motion of the vehicle’s suspension well. This can cause more stress and load to be placed on the wheel bearings, leading to excessive wear and tear. Over time, this extra stress can cause the bearings to fail. Misaligned shock absorbers can cause the vehicle’s wheels to tilt or lean, which can put additional stress on the wheel bearings and create uneven wear on them.

Regular maintenance and inspections of the suspension system can help detect any problems early and prevent costly repairs in the future. 6. Incorrect tyre pressure can affect the life of a car’s wheel bearings. Tyre pressure has a significant impact on the performance and lifespan of a vehicle’s tyres, and as a result, it can also affect the wheel bearings.

When the tyres are underinflated, they can cause the wheel to tilt, which places more stress on the bearings. This extra stress can cause the bearings to wear out much faster than they otherwise would. If the tyres are overinflated, the tyres will be more rigid, causing more shock loads being sent through the bearings. This can lead to excessive wear and tear on the bearings and shorten their lifespan.

Over an extended period of time, the added stress to the wheel bearings due to incorrect tyre pressure can cause permanent damage and wear on the bearings. Eventually, this can lead to a failure of the bearings, which can cause a safety issue while driving.

Driving with worn out front bearings poses a significant danger to road safety. Worn out front bearings can cause erratic handling and braking issues. It can increase the likelihood of an accident

RECENT POSTS & TIPS

- How to Trace a Fault in an EV High Voltage Battery

- Never Lose Your Car Keys Again

- Cross Section Of A Typical Water Themostat

- Testing of EV AC Electric Motor Phase Resistance Balance Test of The Windings

- Brake Fade

- Instructions for Jump Starting a Car

- Low-Pressure Exhaust Recirculation Filter (ERF)

- Reasons for front wheel bearings to breakdown

- Brake Cylinders Failure - Detection & Consequences

- Pollen Filters

- Will a DPF regeneration cure the blocked exhaust issue?

- Why should I change the oil filter each time I change the engine oil in my car?

- What Is AdBlue ?

- Origins of Suspension Systems for Modern Vehicles

- Parasitic Battery Drain

- ELECTRIC VEHICLES – A SIMPLE EXPLANATION

- GIL’S FORESIGHT, ELECTRIC VEHICLES WERE COMING

- MECHANICS OF VARIOUS BRAKE SYSTEMS

- SCAN TOOLS DO NOT FIX CARS. HIGHLY QUALIFIED MECHANICS DO.

- TOYOTA PRIUS HYBRID BATTERY REPAIR