Blog

SCAN TOOLS DO NOT FIX CARS. HIGHLY QUALIFIED MECHANICS DO.

Toyota Prius. Customer complaint, Intermittent no start.

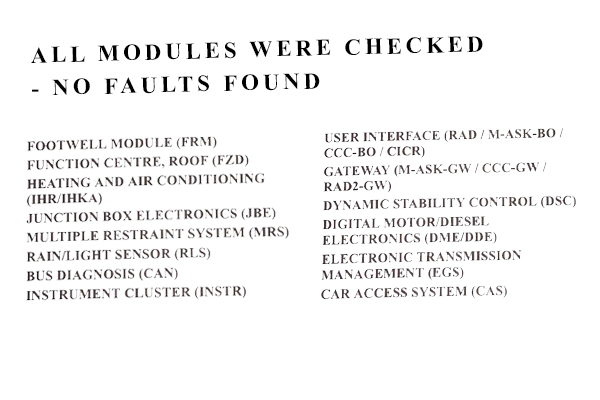

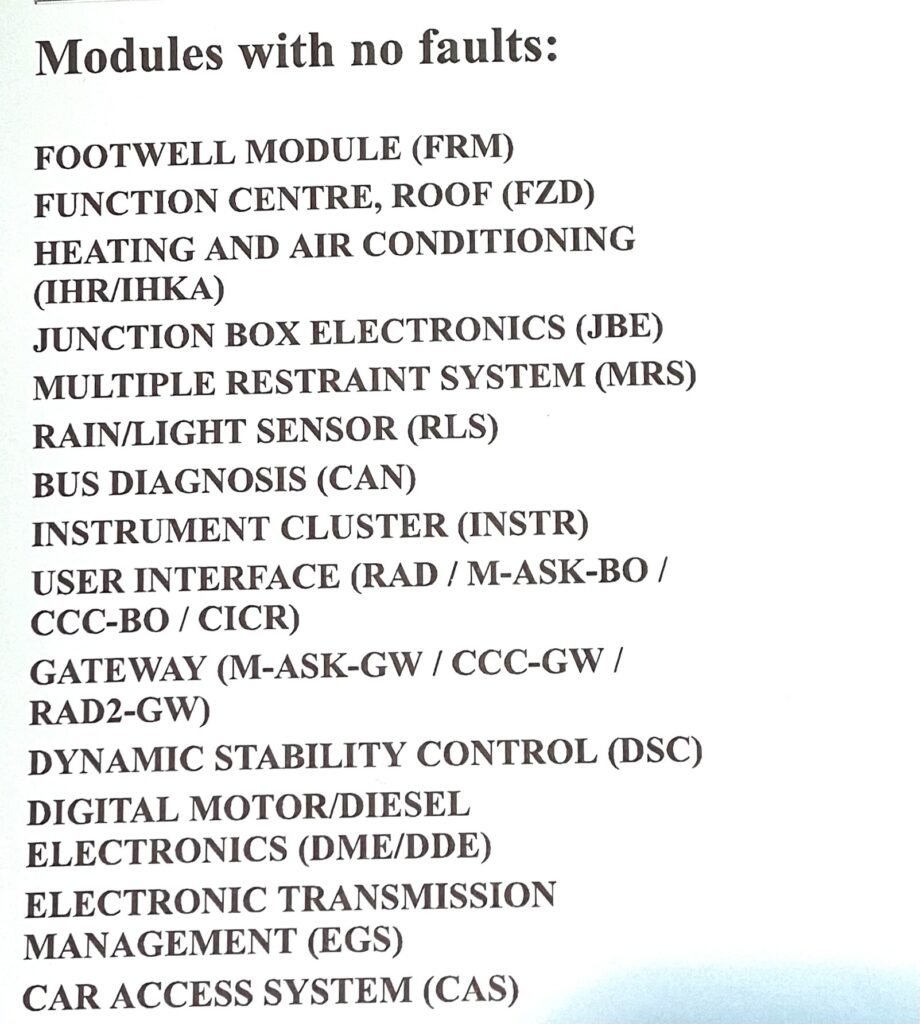

We connected the scan computer to the car to carry out the overall health check.

The scan tool found NO ERRORS in the engine or any related systems, see the live data readings below:

In these cases the technicians are not getting any direction from the car’s computers. They are virtually flying blind. This is where their intimate knowledge and years of study come to the fore. They need to go decide on a direction of investigation. It is important to compare the various readings looking for variations to be in line with what expect and query any that give out of spec readings.

The DC to Dc charging system was showing the correct charging voltage. The next stage was connecting an oscilloscope to the Auxiliary battery. Here it was discovered that the reading at the battery did not match the live data.

The following strategy test direction was implemented:

The next stage was to connect the oscilloscope lead to battery negative post and the other lead to the terminal and load the electrical system to test for Voltage drop by connecting the oscilloscope lead to battery negative post and the other lead to the chassis connection loading the electrical system and tested for voltage drop.

We then connected an oscilloscope lead to the battery negative post and the other lead to the engine ground loading the electrical system to test for voltage drop.

We then connected an oscilloscope lead to battery Positive post and the other lead to the battery terminal loading the electrical system to test for Voltage drop.

We then connected the oscilloscope lead to battery Positive post and the other lead to the DC/DC Charger terminal once again loading the electrical system to test for Voltage drop.

We had to remove the covers to access the high voltage battery secure area.

The procedure to protect the technician when accessing high voltage battery.

One must place an insulated floor mat next to vehicle for the technician to stand on, ensuring that there is no earth leakage through the technician to earth. Before donning the high voltage insulted gloves they must be tested each time. Only then does one remove the high voltage shut off connector and the high voltage access cover.

As part of the safety procedures the technician has one hand held firmly against their back, this is eliminate the chance of a spark finding it’s way through the body. The technicians must be ever vigilant as they are working in a high risk environment.

Using a mega 1000 volt protected meter we inspected the voltage at cut off relays for leakage through the wiring.

We then continued tracing along the circuit until we found the source of the intermittent voltage drop which was a really badly corroded connection. The contacts were thoroughly cleaned and tightened.

The parts that had to removed to get access to the fault were replaced

This was a classic case that highlights the fact that neither on board computers or very sophisticated scan tools fix faults. At best they only give an indication of where a fault might be. In this case there was no indication from the car’s onboard computers.

It takes a highly educated technician to trace and repair today’s modern cars.

RECENT POSTS & TIPS

- Cross Section Of A Typical Water Themostat

- Testing of EV AC Electric Motor Phase Resistance Balance Test of The Windings

- Brake Fade

- Instructions for Jump Starting a Car

- Low-Pressure Exhaust Recirculation Filter (ERF)

- Reasons for front wheel bearings to breakdown

- Brake Cylinders Failure - Detection & Consequences

- Pollen Filters

- Will a DPF regeneration cure the blocked exhaust issue?

- Why should I change the oil filter each time I change the engine oil in my car?

- What Is AdBlue ?

- Origins of Suspension Systems for Modern Vehicles

- Parasitic Battery Drain

- ELECTRIC VEHICLES – A SIMPLE EXPLANATION

- GIL’S FORESIGHT, ELECTRIC VEHICLES WERE COMING

- MECHANICS OF VARIOUS BRAKE SYSTEMS

- SCAN TOOLS DO NOT FIX CARS. HIGHLY QUALIFIED MECHANICS DO.

- TOYOTA PRIUS HYBRID BATTERY REPAIR

- DIAGNOSING A FAULTY FUEL PUMP

- NEW TYRES FITTED OR WHEELS ROTATED