Blog

ELECTRIC VEHICLES – A SIMPLE EXPLANATION

HEV Hybrid Electric Vehicles with Internal Combustion Engine

These are powered by both a petrol-fueled internal combustion engine and a battery-powered electric motor. Both can work either independently or simultaneously. The internal combustion engine recharges the battery. The hydrocarbons given off are much less than a plain internal combustion engine. They have saved vast quantities of hydrocarbons entering the atmosphere over 20 years and removed the driver angst of not reaching ones destination due to lack of battery delivered power.

PHEV Plug in Battery Charge Hybrid Vehicle with Internal Combustion Engine

Is recharged charged from a plug-in recharge station. The vehicle runs off the battery and will only use its internal combustion engine as a back-up should your electric motor’s battery run out. The internal combustion engine is rarely used in city driving. The ICE is insurance in case you do not make it to the next recharge station.

BEV Battery Only Electric Vehicle

These vehicles recharge from plug in charging stations only.

Travel distances and distances are the limiting factors at this stage. As batteries are improving and charging stations become more ubiquitous this will be more attractive as a choice should the recharge time become shorter. For people living in units access to home chargers is going to be challenging.

FCEV Fuel Cell Electric Vehicle Run on Compressed Liquid Hydrogen

These vehicles draw their power from liquid Hydrogen Cells which gets converted into electrical energy to drive the electric motor. In the process they do not give off any hydrocarbons. These vehicles have a much longer travel distance than the battery only electric vehicle. The refuel time is similar to that of petrol diesel cars.

It is very doubtful that electric vehicles will ever match the low cost of the internal combustion engine. It is thought that the holy grail of electric vehicle batteries will be the solid state battery. So far all attempts to produce one have failed despite billions of dollars invested in research.

EV cars are gaining ground as personal modes of transport in Australia. Over time Governments are likely to mandate the all cars to be electric only.

How to recharging stations work?

A brief and simplistic explanation of the electrical changes that take place in an EV charging station.

The unit is plugged into a 240volt AC (Alternating Current Source). This is the standard Australian domestic supply.

This 240 volt leads to the primary side of a special transformer. The secondary side of the transformer increases the voltage. It has the ability to produce two AC outputs which are out 90 degrees of sync with each other. On the one legs as the voltage increases from zero to its peak the second output decreases down from zero to its nadir.

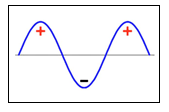

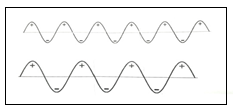

Before combination they would looks like a series of ocean waves having peaks and troughs. Visualise an imaginary line running horizontally midway between the peaks and the troughs. This is what alternating AC voltage looks like. Starting at zero volts at the horizontal line it increases in voltage to its peak before descending to the horizontal line, which is its datum point. From there it continues to descend, the voltage going negative until it reaches its nadir and then commences upwards toward zero. This rise from zero to its peak, descend to zero, continue on to its nadir and then rise again to zero is one cycle. In Australia our mains home is AC voltage at 240 volts and 50 cycles per second.

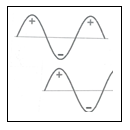

This 240 volt 50 cycle is fed into the primary side of a transformer. The function of the transformer is to increase the voltage and send out two feeds. One whose sine wave has been moved through 90 Degrees as one phase rises the other phase falls. As the one phase becomes positive the other phase becomes negative at an equal rate and

intensity

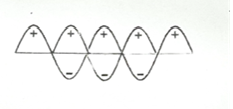

These two blended voltages are fed into a diode bridge which eliminates all negative potions of both cycles so that the resulting wave form looks like a row of Eskimo igloos touching each other at their bases.

The straight line base is the negative (zero volts). The positive arcs are rising and falling 100 times per second. Direct Current DC voltage must have a constant positive voltage. This ripple needs to be smoothed out. After passing through more components it emerges as a sent smooth ripple free usable DC voltage. Just for interest sake this DC voltage is only 70% voltage of the unsmoothed ripple voltage. This is fed to the rechargeable battery in the car for charging to take place.

The actual circuitry is very much more complex. The circuit is protected by fuses and current and voltage limiters.

Onboard High Voltage battery Servicing

You would have noticed on your conventional car the corrosion that forms on the two terminal posts of your 12 volt starter battery. The high voltage EV battery has many such connections which also have corrosion forming at their multiple contacts.

With the conventional 12volt car battery if one cell dies the battery becomes scrap and is sent for recycling. Just FYI 98% of all 12 volt car batteries can be recycled.

The basic unit in certain EV cars are a pack is six individual cells linked in series built into one batteries pack. These packs too are linked in series to deliver the high voltage that is required.

Should one of the six packs become faulty it must be replaced. The corroded bus bars connecting each pack can produce the same corrosion that one sees on the terminals of a conventional 12 volt car battery. This is not good. Each buss bar must be removed and cleaned, the terminal that holds it in position also needs to be toughly cleaned of all remnants of the corrosion. If it is not completely clean the remnants will seed more corrosion.

Even one dead cell in the multitude of cells that make up the battery pack will compromise the efficiency of the whole battery.

Danger Beware

All NSW electric and hybrid vehicles have on their number plate a symbol to warn first responders of the dangerously high voltages present in this car. EV in a blue triangle, an H in a yellow pentagon.

Working on the high voltage battery pack is a dangerous procedure. The technician needs to wear high voltage Personal Protective Equipment PPE rated to at least 1000volts. They must have undertaken the special training and received certification from TAFE. A barrier need to be set up around the vehicle in order to prevent others wandering to the danger zone.

Torque comparing Internal Combustion Engines and Electric Motors

Internal Combustion Engines have very low torque at low speeds hence the need for gears and transmission systems. Electric motors have very high torque right from the start. Their pull away power and speed is superior to even very best of ICE cars.

The greater the number of cylinders in an internal combustion engine the smoother the operation will be.

The motive force in an internal combustion engine is the explosion of the petrol/diesel trapped between the piston and the cylinder. As the explosion takes place the piston is forced downward. The other end of the piston head is connected to the crankshaft. The downward thrust of the piston causes the crank shaft to rotate. In a four cylinder engine there is a 90 degree rotation of the crankshaft between firings. On a six cylinder engine only 60 degree between rotations and on a 12 cylinder engine only 30 degrees.

This same principle applies in an electric motor. The more windings in the motor the smoother the force on the shaft will be and in turn all the way down to the tyres on the road. The motive force in this case is magnetism. No exhaust fumes no oil leaks no loud engine noise. Only a smooth purring sound.

Fact 1

It is well known that if you bring two magnets close to each other they will repel each other, or swivelled through 180 degrees they will attract each other until they are touching. The stronger the magnet the stronger the force they exert on each other. Magnets have a north and a south pole. Bringing the 2 north poles together and they will repel each other. Bring a north and south near each other and they will attract each other.

Fact 2

While passing a coil of wire through the field of force of a magnet, electric voltage will be generated in the coil. while the coil is moving through the field of force of the magnet. If the coil is static and the magnet moving a current will still be generated. “Stop the magnet relative to the coil and the current stops.”

Just as the greater the number of cylinder’s in an internal combustion engine, so will the electric motor in an electric vehicle run smoother and with more power based on the number of windings and phases of the AC voltage driving the motor.

What makes ICE cars go faster and what make EV cars go faster

In an ICE Internal Combustion Engine as one depresses the accelerator pedal more petrol/diesel is fed into the engines cylinders, which makes a bigger explosion propelling the conrod at a higher speed to the camshaft and this increases the camshaft rotational speed and thereby making the car go faster.

In an EV car the voltage reaching the windings of the motor (for the purposes of this article) is a constant. So why does depressing the accelerator make the car go faster?

The engine turns because of the AC voltage applied to the winding coils in the motor. By feeding the windings with a higher or lower cycle frequency the motor is forced to increase or decrease its speed to match the increase or decrease of frequency of the AC cycles per second.

The inverter is a very special piece of electronic engineering and has some highly sophisticated circuitry.

The high voltage battery is feeding a DC voltage into the inverter.

While converting AC voltage in to DC voltage is a relatively easy thing to do. (See above “Charging Station”)

Turning DC in to AC produces many challenges.

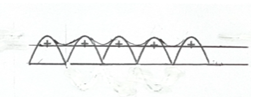

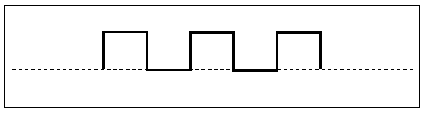

A DC flip flop switching circuit will produce a pattern like the one below. To make the resulting Wave behave like a sine wave requires fractions of a second Flip Flop variable switching of the DC circuits.

The inverter has the ability to generate a wide range of variable AC sine waves. These in turn speed up or slow down the motor.

The inverter contains a circuit that varies the frequency of the sine waves either slow or fast.

When is a motor not a motor? When decelerating the spinning motor acts as generator.

“Regen” or regeneration occurs when you are not accelerating and the car is either cruising or decelerating. The motor acts like a generator returning power to the battery to recharge the battery and increase travel distance. The electrical current generated is AC or Sine wave. This sine wave needs to be converted to DC in order to recharge the batteries similar to the normal home charger.

The “Regen” also tends to slow the forward motion of the car thereby extending the life of the brakes.

The inverters have “Variable Frequency Drive” generators. Just for reference normal household AC frequency is 50 Cycles / Second.

The motor speed is controlled by the frequency of the cycles of the voltage applied to the motor. The rotational speed of the motor is controlled by the increase or decrease of the voltage frequency. As the cycles per second increase so too will the motor speed.

At the heart of this system is a component IGBT it is currently the fastest possible switching of electric currents, it achieves the lowest possible switching losses.

Weather makes a difference. Where you live makes a difference

In any brand not of all the same models are identical. Now this sounds crazy, but it is true!

Living in a permanently either a hot or cold area will affect the length the distance you will be able to travel before recharging.

Use of heater or air conditioner will have an impact on the distance you will be able to travel.

It is well known that with petrol and diesel engines that they consume more fuel when on uses ones air-conditioner, so too is it with EV cars: Distance traveled with air-conditioner working will be less than without use of air-conditioner.

In cooler weather use of seat warmers should be considered before using cabin heating

In cold weather one should take extra steps to keep the battery warm. Some models have a schedule departure feature which will save you energy loss during your journey by pre-heating the battery.

Tips to conserve energy and extend you driving range

Drive conservatively and smoothly, suddenly and continuously accelerating and decelerating is not doing your battery any favours. Using natural ventilation when conditions are mild instead of air conditioning will conserve battery energy. Under moderately cool conditions seat warming might surface instead of using the cabin heating ventilation system.

RECENT POSTS & TIPS

- How to Trace a Fault in an EV High Voltage Battery

- Never Lose Your Car Keys Again

- Cross Section Of A Typical Water Themostat

- Testing of EV AC Electric Motor Phase Resistance Balance Test of The Windings

- Brake Fade

- Instructions for Jump Starting a Car

- Low-Pressure Exhaust Recirculation Filter (ERF)

- Reasons for front wheel bearings to breakdown

- Brake Cylinders Failure - Detection & Consequences

- Pollen Filters

- Will a DPF regeneration cure the blocked exhaust issue?

- Why should I change the oil filter each time I change the engine oil in my car?

- What Is AdBlue ?

- Origins of Suspension Systems for Modern Vehicles

- Parasitic Battery Drain

- ELECTRIC VEHICLES – A SIMPLE EXPLANATION

- GIL’S FORESIGHT, ELECTRIC VEHICLES WERE COMING

- MECHANICS OF VARIOUS BRAKE SYSTEMS

- SCAN TOOLS DO NOT FIX CARS. HIGHLY QUALIFIED MECHANICS DO.

- TOYOTA PRIUS HYBRID BATTERY REPAIR